You are viewing your 1 free article this month. Login to read more articles.

Paper pulp shortage adds to supply chain woes with extra delays and costs

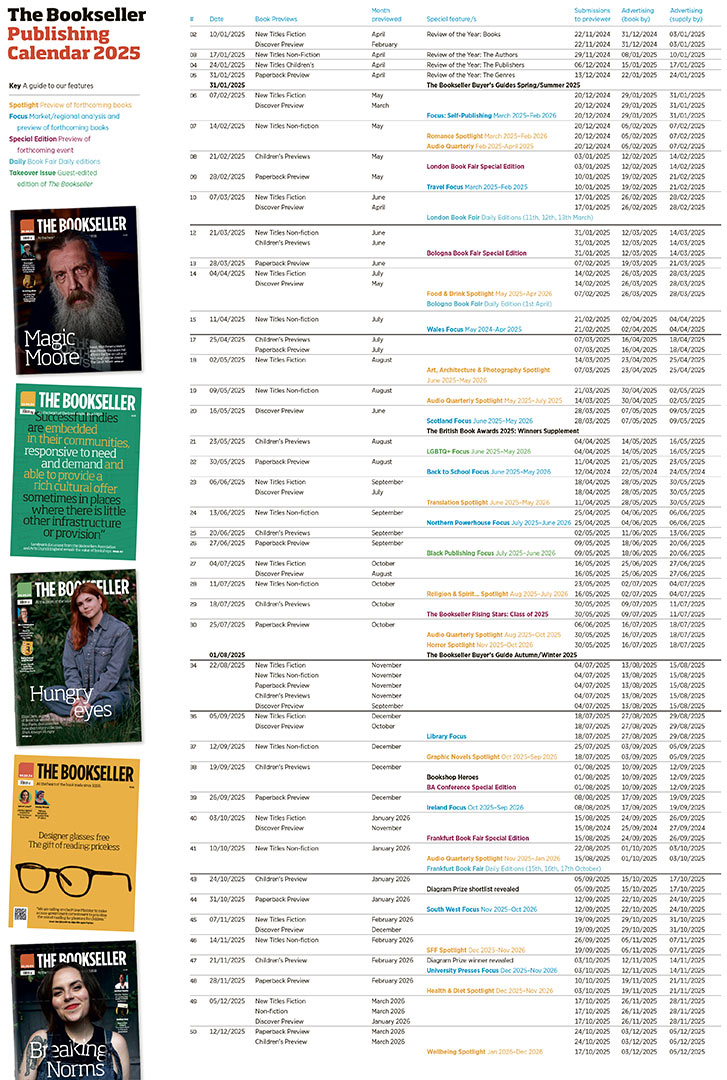

A global shortage of paper pulp is causing huge disruption to the industry with delays of up to 12 weeks in getting paper from suppliers, a knock-on effect on lead times and fears over pre-Christmas reprints.

Companies say the issue has predominantly affected the finer-quality paper often used for illustrated non-fiction. With a shortage of pulp, some European printing firms are not getting the material from suppliers for eight to 12 weeks, instead of the usual few days. Costs have spiked.

Nick Wells, founder and publisher of Flame Tree Publishing, explained that a shortage of both paper pulp and UK HGV drivers meant local print lead times have doubled for bestselling paperbacks.

Additionally, sea freight and container shortages are causing cost increases up to 400% for the indie, alongside two-month delays on seasonally sensitive books, gifts and calendars. Wells described the situation as caused by a mixture of Covid-19, Brexit, US customs duties, and increasing climate regulation in China–“all of which affect pulp manufacture, print capacity and delivery to publishers, and retail”.

He said world events such as the pandemic had forced major ports in China including Shanghai and Ningbo to close, leading to longer wait times for delivery. Earlier this year the blockage of the Suez Canal, one of the busiest shipping lanes in the world, also meant books bound for shops were late.

Wells explained: “Last year China began to enforce their pollution regulations to stop manufacturing waste polluting local rivers and water supplies to large cities, That shut down several key pulp manufacturers and caused a significant supply problem which continues today.

“Imposition by the US under President Trump, and continuing under Biden, of customs duties on paper goods has caused increased costs and custom checks which, with the impact of Covid, quarantine and stay-at-home orders for logistics and warehouse operations have had massive knock-on effect on ports, causing huge congestion in Los Angeles with ships waiting and diverting.

"All of these issues sit behind the pulp shortage at a time when delivery schedules and capacity is very tight worldwide.”

At the Irish Academic Press, production staff said reps at various printers are all experiencing delays from their suppliers and are being charged more as demand outstrips supply, with prices continuing to rise month on month.

“Ordinarily, this was taking a matter of days and the print production would proceed from there,” a spokesperson told The Bookseller. “This year our printers are being quoted anywhere from three to six weeks just to get the paper in stock. That doesn’t take into account the time to produce and deliver. Our worst quoted lead-in times this year have been over 12 weeks, where a similar job was taking four to five weeks in 2020.”

They added: “While our printers have done their best to absorb some of the cost, the increase has inevitably been passed onto the publishers. We have comparable quotes from 2020 and 2021 and the increase in unit cost is clear to see.”

Publishers are worried that reprints, particularly in the busy autumn period and lead-up to Christmas, will suffer as a consequence of the delays. Irish Academic Press m.d. Conor Graham said: “We can’t be sending for a reprint order in the middle of October if we’re not getting it until 5th January, obviously.

“The ultimate knock-on effect of this is we’ve had to spend significantly longer talking to our book trade customers about their forecasts for particular books, not just the first three to six week sales but October right through to Christmas.”

Ivan O’Brien, m.d. of Dublin-based The O’Brien Press, said he was experiencing problems with a “major" paper shortage and that printers were having significant issues with sourcing and maintaining supply of paper. “When anything goes wrong it’s taking longer than usual to resolve,” he said. “Usual flexibilities around quantities and delivery times have gone, and getting reprints in this autumn is going to be a real challenge."

The shortage is having wide-reaching ramifications for companies like Wiley with large operations in the US. A spokesperson for Wiley said: “There have been specific paper shortages communicated to us by our US printers. We are working with them to prioritise work and adjust schedules so we can continue to meet demand. We have not seen the same level of paper shortages in the UK/EMEA market at this point.”

Sales director at Magic Cat, Adrian Greenwood, said that the press was not experiencing delays with pulp as its products were predominantly wood-free but the capacity to do quick reprints was “always fraught at this time of year”.

He explained: “You get the panic after Super Thursday when the runners and riders finally start to emerge – that puts pressures on Europe [and] mono printers due to time constraints.”

However, he stressed freight problems “remain the overriding issue”.